What Makes a Good Power Converter for Industrial Use?

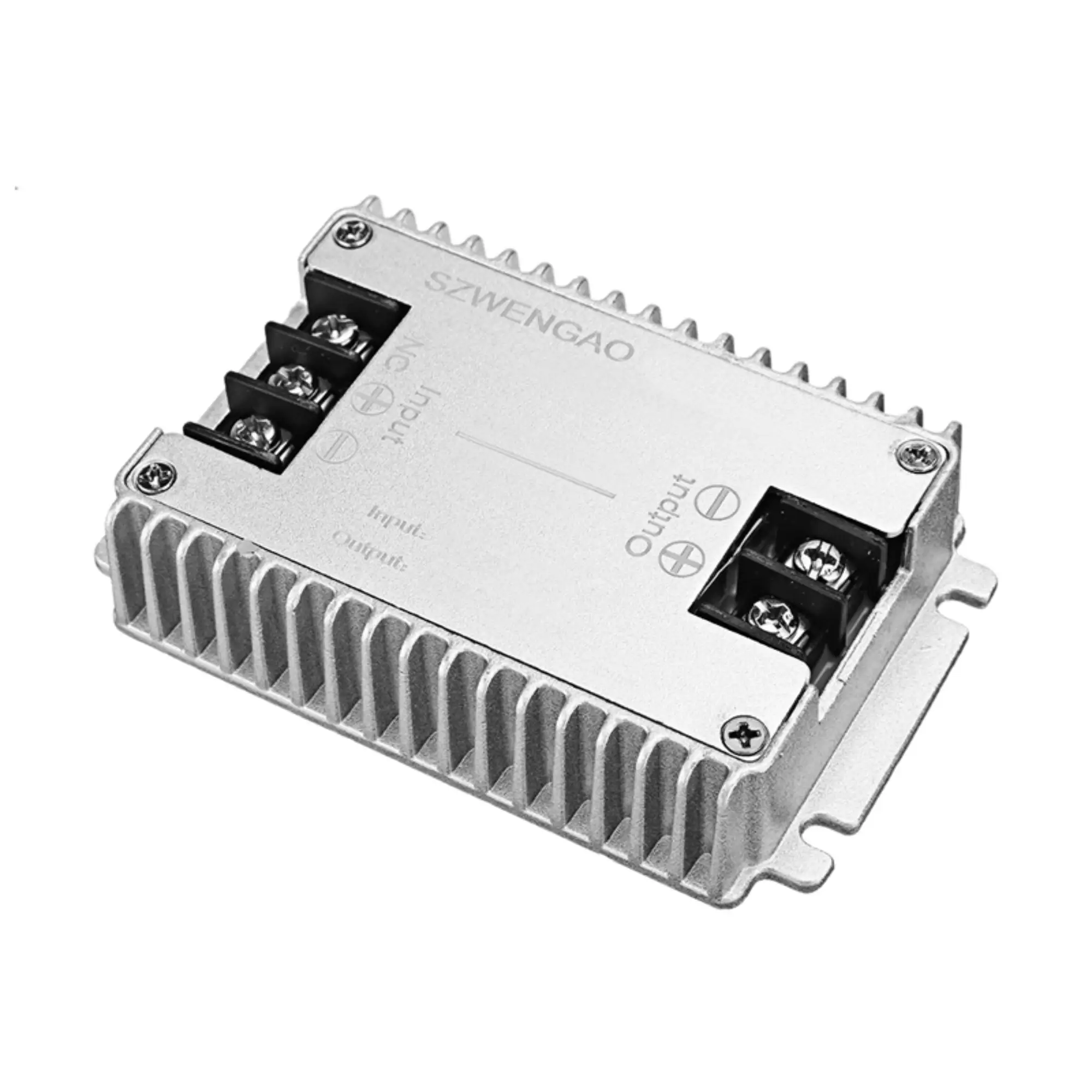

Industrial operations rely heavily on a stable power supply, and a key component here is the Power Converter. But what exactly makes a good one for industrial use? It’s not just about converting voltage. When dealing with tough conditions, various kinds of equipment, and long-term reliability, there are particular interests. Here are the features that best quality Power Converter helps industrial applications.

Focus on Long-Term Operational Efficiency

Let’s be real—industrial facilities run for hours, even days on end. This is the reason why the Power Converter you choose shouldn't be an energy hog. High operational efficiency is no long a goal. It’s a must to keep power supply operational costs and energy waste to a minimum. Just consider the the economic waste generated with a poorly efficient converter. More heat generated with a poorly efficient converter will not only waste energy, but will also shorten the lifespan of the the device.

Power solution companies with years of experience like szwengao design their Power Converters with efficiency in mind. For example, their buck DC-DC converters are designed for effective use of power, ensuring that most of the input power is converted to output and less is wasted as heat. Economic savings are not the only advantage of such efficiency. With less heat generated, the Power Converters would not need additional cooling systems as often. In industrial environments, where every dollar and every square foot counts, these savings are enormous.

Over time, even small efficiency improvements are significant. Consider a facility that has several Power Converters systems, with each having at least a 5% improvements in efficiency. Such savings significantly lowers the total energy expenditure for the facility over a year. This is why savvy industrial operators focus less on the initial cost of a converter and more on the long term efficiency potential, knowing that it would result in lower energy costs, less frequency of replacements, and fewer converters in the long run.

Focus on Durability to Handle Industrial Settings

It’s a fact that industrial settings are challenging. Dust, moisture, temperature changes, and vibrations are rampant, and a delicate Power Converter will not survive. So, if you are selecting one, durability will be a major consideration.

Looking for protective features in a Power Converter is essential. Many quality Power Converters have waterproof or dustproof designs. Take a look at the IP65 rating for example. Covers waterproof splashes and keeps dust out, which is ideal for factories or outdoor industrial setups. Also, Industrial-grade components is a must. Cheap components will only last a short time and fail under the stresses applicable in industrial usage.

Marine and RV power solutions are great examples of power solutions that need to manage the elements and constant movement. The same goes for industrial power converters. These need to be built to last. The brands that make high-quality industrial converters understand this and the converters are built to be testedand endure these extreme conditions before ever being sold. When converters are built to last, industrial facility operators have peace of mind from knowing that the facility will be able to run continuously, and when the converters do need repairs, they will be quick and the downtime will be minimal. This equals less stress and more focus on more important tasks.

Tailor to the Project and Equipment in Question

Industrial applications are not a case of one size fits all. You have one piece of equipment that may need a 12 volt output and the next may need 24 volt. Then a third machine may need to have a 12 output and one that may need a 24 volt and the last machine may need a variable voltage range. A power converter will need to be adaptable to these varying requirements, or have the ability to be modified to adapt to the equipment in question to meet these different power requirements. A good power converter will have these necessary configurations.A variety of product models available can benefit customers. Some power solution providers offer over 500 models of Power Converters, covering everything from buck and boost converters to buck-boost versions. This variety means you can find a converter that matches your exact voltage and current requirements without having to compromise, and, in many cases, custom solutions can be a lifesaver for unique industrial setups. If your facility has special needs that off-the-shelf models can’t meet, working with a provider that offers customized Power Converters can make all the difference.

This also provides ease of use internationally. Industrial operations often have facilities in different countries, each with its own power standards. A good Power Converter can tackle the differing standards whether it’s for use in the USA, Europe, Australia, or elsewhere. Importantly, providers that export to over 130 countries usually have this built in, making it easier to standardize power solutions across global facilities. No one wants to deal with the hassle of buying different converters for every location—versatility simply clears that.

Don’t Hesitate to Seek Expert Help for Integration

No Power Converter will be beneficial if you cannot effortlessly incorporate it into your current industrial infrastructure. This is where expert assistance is crucial for making a power solution really dependable for industrial applications.

Consider the steps involved: you select a Power Converter, but you must then put it in place, join it to your machinery, and ensure it interacts with your other devices. Having a point of contact is vital, and it should be no more than a phone call away. Quality assistance is characterized by rapid response times and the avoidance of lengthy delays for help with a production-stopping issue. Expert assistance includes knowledge of industrial systems—advice on installation, troubleshooting, and long-term maintenance to ensure your converter remains functional is invaluable.

Top providers have partnerships with well-known companies across different industries, including automotive and telecommunications. These partnerships demonstrate the confidence and dependability leading companies have in their Power Converters and the associated support services. When you select a provider with this caliber of professional assistance, you are not just acquiring a product. They become a partner in ensuring your industrial operations are running properly and with minimal downtime. In industrial applications, time equates to money, and the losses that can be attributed to poorly integrated converters are significant.

Ultimately, a suitable Power Converter for industrial applications must satisfy a number of important criteria: high efficiency to minimize costs and heat production, dependability to survive harsh conditions, flexibility to accommodate a variety of demands, and the expertise of professional support to guarantee seamless integration. All of these factors combine to deliver a power solution that is reliable and enables industrial operations to continue running seamlessly. These aspects should be your focus when choosing a Power Converter, whether you are in need of a standard solution or a customized one.

Recommended Products

Hot News

-

Application Advantages of Non-Isolated BUCK Converters Compared to Isolated Step-Down Converters

2024-01-23

-

DC-DC Converters Showcase Remarkable Advantages in Outdoor Off-Grid Applications

2024-01-23

-

DC to DC Battery Charger - Wide input and Noise immunity for dual battery system applications

2024-01-19

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

HY

HY

BN

BN

MN

MN