Buck-Boost DC-DC Converters: The Solution for Variable Voltage Requirements

How Buck-Boost DC-DC Converters Solve Variable Voltage Challenges

Principles of Voltage Regulation

Voltage regulation is essential in electronic circuits, ensuring a stable and consistent voltage output is maintained regardless of variations in input voltage or load conditions. One of the key components utilized in achieving this purpose is the buck-boost converter. This versatile device can both step up (boost) and step down (buck) the voltage, providing flexibility across various applications. It does so by using components like inductors and capacitors to store and transfer energy efficiently, along with switching devices that control the direction and magnitude of the current. These elements work together in a synchronized manner to regulate the voltage, safeguarding sensitive electronic devices from potential damage due to fluctuations. Buck-boost converters thus play a pivotal role in managing power supply systems where variable voltage scenarios are inevitable.

Handling Input Voltage Fluctuations

In power systems, input voltage fluctuations can arise from various sources, such as changes in load demand, environmental factors, or system disturbances. These fluctuations can adversely affect output performance, but buck-boost converters offer effective solutions to tackle these challenges. They achieve stable output despite variations in input voltage through techniques like pulse-width modulation and feedback control mechanisms that adjust the operation of the converter in response to changing conditions. Examples of these converters in action include their use in solar systems or telecommunications where stability is crucial. Additionally, buck-boost converters have consistently proven their reliability and effectiveness in maintaining performance, even under fluctuating conditions, as evident from numerous real-world case studies.

Output Stability in Dynamic Conditions

Output stability is critical for sensitive electronic devices, which demand consistent power levels to function correctly. Buck-boost converters excel in maintaining this stability, especially under dynamic load conditions where power requirements can shift rapidly. They adapt to these changes by effectively managing energy distribution within the circuit, ensuring that fluctuations in demand do not disturb the output voltage integrity. For instance, statistical data suggests that buck-boost converters consistently deliver stable performance across varying conditions, thereby preventing disruptions in device operation. Consequently, these converters are instrumental in applications that require unwavering power supply, further showcasing their indispensable role in modern electronic systems.

Product Recommendations

For practical solutions to variable voltage challenges, consider these reliable and efficient DC-DC converters:

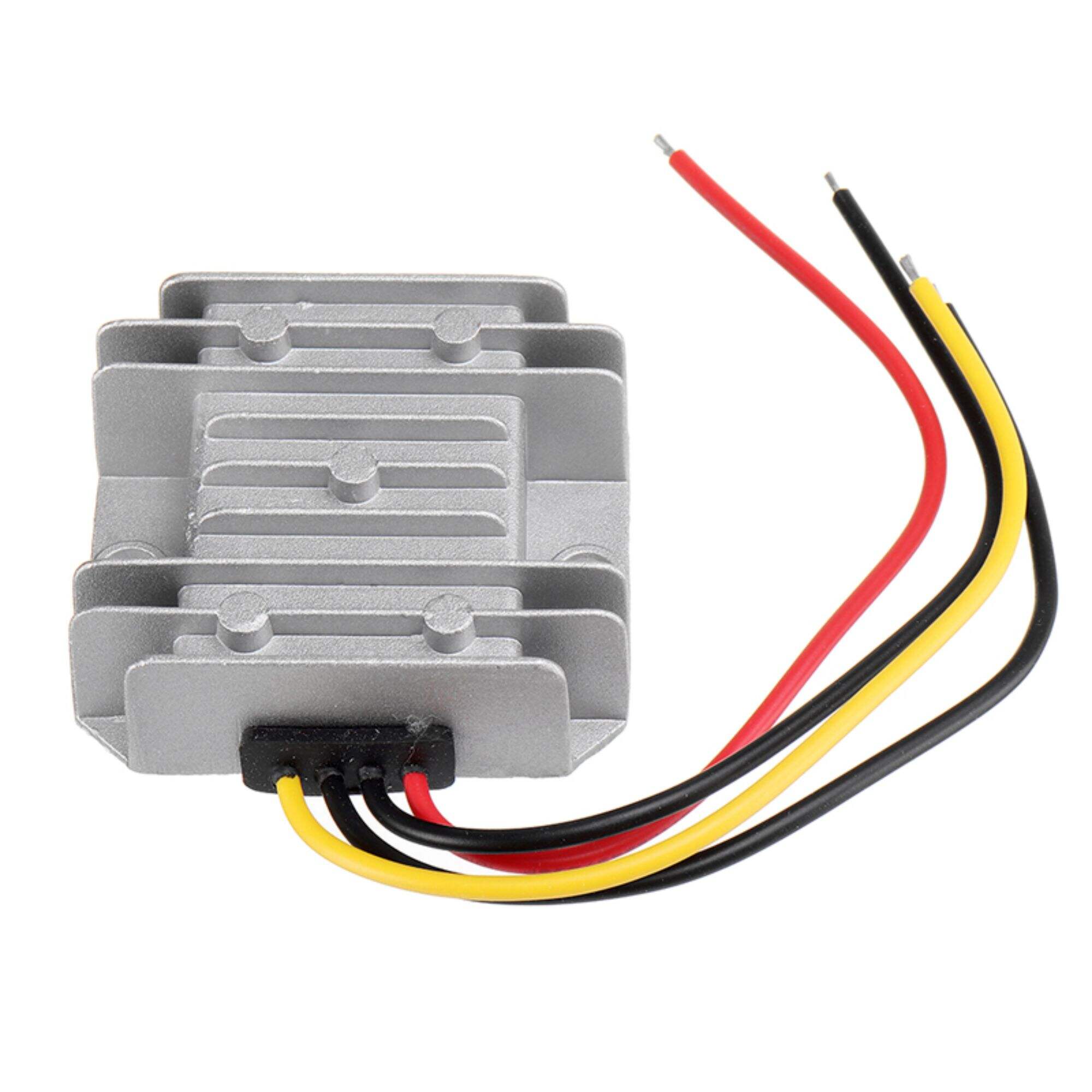

- [Manufacturer 10-44V to 28V 30A 840W DC/DC Converter Regulator Waterproof Buck Boost Power Supply for Cars Boats](#):

- This product offers robust performance and weatherproof protection for automotive and marine applications.

- [Manufacturer 20-80V to 48V 4A DC DC Buck Boost Converter Voltage Regulator Stabilizer for Telecommunications Vehicles Solar System](#):

- Ideal for telecommunication setups and solar systems, ensuring consistent power distribution even under fluctuating conditions.

Each product combines cutting-edge technology with practical design, providing efficient and reliable solutions for maintaining voltage stability in demanding environments.

Key Applications of Buck-Boost Converters

Automotive Power Systems

Automotive power systems face numerous challenges due to the fluctuating voltage demands of modern vehicles. These systems require stable and reliable power to manage functions such as lighting, infotainment, and engine control systems. Buck-boost converters are particularly effective in automotive applications as they can adjust voltage levels to match varying load demands. For instance, these converters are used in electric vehicles to ensure the battery's power supply remains consistent regardless of the vehicle's speed or battery charge state. According to industry reports, there is a growing trend in the integration of buck-boost converters in electric vehicles, driven by the demand for efficient energy management solutions.

- Numerous challenges in modern vehicles' voltage demands

- Buck-boost converters adjust voltage to match varying load demands

- Growing trend in EV integration according to industry reports

Industrial Automation Solutions

In industrial automation, machinery and equipment require constant and precise voltage supply to operate effectively. Buck-boost converters play a crucial role in providing the necessary voltage adjustments to keep these systems running smoothly. Case studies have proven their effectiveness in maintaining operational efficiency in sectors such as manufacturing and robotics, where voltage needs can vary significantly during operations. The future of industrial automation is likely to see an increased adoption of buck-boost converters, especially as systems become more complex and the demand for precision power grows.

- Need for constant voltage supply in automation

- Proven effectiveness in manufacturing and robotics

- Future trends likely to increase converter adoption

Renewable Energy Integration

Renewable energy systems, such as solar and wind, often encounter challenges related to voltage regulation due to the unpredictable nature of their energy sources. Buck-boost converters are essential in these systems to optimize the energy output and ensure a stable power supply. Research studies have demonstrated the effectiveness of these converters in managing energy fluctuations and enhancing the overall efficiency of renewable energy installations. As the adoption of renewable energy continues to expand, buck-boost converters will become increasingly vital in managing the integration of these technologies into the grid.

- Renewable systems face voltage regulation challenges

- Converters optimize energy output for stability

- Proven efficiency in research studies and growing renewable adoption

In conclusion, buck-boost converters are versatile tools essential for managing voltage challenges in various applications. As industries continue to innovate and adopt new technologies, the role of these converters will undoubtedly become more significant.

Critical Features for Reliable Voltage Conversion

Wide Input Voltage Ranges

A wide input voltage range is crucial for the versatility of buck-boost converters, enabling them to function effectively in diverse applications. This feature allows converters to adapt to varying voltage inputs, maintaining steady output regardless of fluctuations in the input source. For instance, buck-boost converters with input ranges from 10-50V or 20-80V are ideal in scenarios where power supplies vary significantly, such as renewable energy systems and industrial automation. The technical specifications typically define these ranges, ensuring they are suitable for specific applications requiring dynamic voltage adaptability. Versatile applications like battery systems in automated vehicles and renewable energy converters greatly benefit from these wide voltage capabilities, ensuring reliability and efficiency in power supply.

High-Efficiency Thermal Management

Efficient thermal management is key to maximizing converter performance and reliability. Proper thermal management ensures the device operates within safe temperature thresholds, reducing the risk of overheating and maintaining efficiency. Buck-boost converters incorporate features such as heat sinks and advanced thermal materials to enhance their heat dissipation ability. Comparing different designs, some converters use active cooling systems, while others harness passive techniques like increased surface areas for natural heat expulsion. High-efficiency thermal management extends the lifespan of converters and supports sustained, reliable operation, making it a critical component in power-sensitive applications like industrial automation and electric vehicles.

Protection Circuitry Essentials

Protection circuitry is essential in buck-boost converters to prevent electrical failures and enhance operational safety. Common types of protection include over-voltage, under-voltage, short-circuit, and overload protections, each guarding against specific problems that could compromise the converter's functionality. Inadequate protection can lead to higher failure rates, potentially damaging equipment and causing costly downtime. Statistical data indicates that electrical systems lacking proper protective measures face increased risks of malfunction, highlighting the importance of robust circuitry. Ensuring comprehensive protection not only safeguards the converter and connected devices but also supports prolonged and efficient operation in environments ranging from renewable energy systems to automotive applications.

For more information on high-performance buck-boost converters, check out the 10-44V to 28V 30A 840W DC/DC Converter Regulator.

Specialized Buck Converters for Specific Voltage Needs

12V/24V to 5V Step-Down Converter for LED Systems

The LED market has experienced remarkable growth, posing new challenges in terms of power supply requirements. Ensuring efficient power delivery is crucial as inconsistent voltage can lead to premature failure of LED components. This is where a 12V/24V to 5V step-down converter becomes indispensable. With its wide input voltage range of 8-36V and high efficiency up to 91.6%, this step-down converter ensures stable current output for optimal LED performance. The Reliable 12V 24 Volt to 5V DC DC Converter showcases how technological advancements contribute to solving power challenges in LED applications.

24V to 12V Automotive Power Regulator

As the automotive industry increasingly shifts towards 24V systems, the necessity for effective power regulation is more apparent than ever. This transition is exemplified by the need for 24V to 12V converters that cater specifically to automotive applications. Designed to efficiently handle a working current of 0-20 Amps and a voltage range of 18-36V, the Reliable 24V to 12V Step-down DC DC Converter addresses these demands. Features like up to 96% efficiency alongside short circuit and overload protections make it a significant asset in modern automotive designs, aligning seamlessly with industry reports emphasizing energy efficiency and system safety.

High-Current 24V-12V Industrial Buck Module

Industrial settings often demand high-current applications, challenging power supply manufacturers to deliver robust solutions. High-current buck modules pave the way for stable and efficient power conversion critical to industrial operations. For example, the High Power 24V-12V Buck Converter supports up to 100 Amps, making it an ideal candidate for intense industrial environments. This converter is designed with advanced thermal management and protection features like over temperature safeguards, ensuring durability and reliability—essential qualities demonstrated through successful case studies in various industrial applications.

Recommended Products

Hot News

-

Application Advantages of Non-Isolated BUCK Converters Compared to Isolated Step-Down Converters

2024-01-23

-

DC-DC Converters Showcase Remarkable Advantages in Outdoor Off-Grid Applications

2024-01-23

-

DC to DC Battery Charger - Wide input and Noise immunity for dual battery system applications

2024-01-19

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

HY

HY

BN

BN

MN

MN