Why is Thermal Management Important in DC DC Converters?

You know the feeling—your laptop or phone gets noticeably warm after some heavy use. That warmth is a simple lesson in electronics: power conversion generates heat. This principle scales up dramatically in the complex, high-power systems we rely on every day, from electric vehicles and 5G base stations to industrial robots and medical devices. While efficient power delivery is the lifeblood of this technology, at its core lies a DC DC Converter, performing the essential task of stepping voltage up or down. This critical function has an inevitable byproduct: thermal energy. Managing this heat isn't just important; it is arguably the most critical factor influencing the converter's performance, longevity, and the overall safety of the system.

The Inevitable Link Between Power and Heat

To understand why heat management must be a priority, we must first look at where the heat comes from. Simply put, a DC DC converter is not a perfect device. During operation, power losses occur within its key components: semiconductors, switching elements, control circuitry, and magnetics (inductors and transformers). These losses manifest as heat. When a converter is rated 95% efficient, it means 95% of the input power is converted to useful output. The remaining 5% is dissipated as waste heat. While 5% may sound insignificant, in high-power systems handling hundreds of watts, this represents a substantial amount of thermal energy that must be addressed. This is the central challenge of power electronics design: achieving the necessary electrical function while effectively managing the resulting thermal output.

The High Cost of Overheating

What happens if this heat isn't properly managed? The consequences range from performance issues to complete failure.

-

Catastrophic Decline in Reliability and Lifespan: Electronic components, particularly electrolytic capacitors and semiconductor junctions, are highly sensitive to temperature. A common industry guideline, often called the "10°C Rule," states that for every 10°C increase in operating temperature, a component's expected lifetime is roughly halved. Poor thermal management doesn't just lead to gradual failure; it dramatically accelerates component aging. It can turn a product designed to last a decade into one that may fail in just a couple of years. This is why investing in a well-built DC DC Converter with superior thermal design is an investment in long-term reliability.

-

Forced Performance Throttling (Derating): When a converter's internal temperature rises too high, its protection circuitry has only one safe option: reduce the output power. This is called thermal derating. For applications like a robotic arm or a telecommunications transceiver, this can result in sluggish operation or a dropped signal at a critical moment. The converter is essentially sacrificing its primary function to prevent self-destruction, which constitutes a significant failure for the system it powers.

-

Compromised Power Density and Size: Heat is the primary obstacle to miniaturization. If heat cannot be effectively removed, designers are forced to use larger components, incorporate bulky heat sinks, and leave more space for air circulation. This directly conflicts with the industry's drive for smaller, more powerful devices. Effective thermal management is what allows engineers to pack more power into a compact DC DC Converter without sacrificing reliability or creating hot spots.

-

A Direct Threat to System Safety: In extreme cases, uncontrolled overheating is a serious safety hazard. It can lead to component thermal runaway, melting insulation, or even become a fire risk in sensitive environments. This is unacceptable in mission-critical fields like medical diagnostics or transportation, where failure can have severe consequences.

Modern Thermal Management: A Multi-Layered Approach

So, how do engineers solve this heat problem? Modern thermal management in a high-quality DC DC converter is a sophisticated, multi-layered strategy that begins at the component level and extends to system integration.

-

Intelligent Component Selection and PCB Layout: It starts with choosing semiconductor switches (like MOSFETs) with low on-state resistance and magnetic core materials that have minimal loss at the operating frequency. The physical layout of the printed circuit board (PCB) is equally critical. Placing high-heat components strategically and using thick copper planes (thermal pads or "pours") helps spread heat across the board, preventing damaging localized hot spots.

-

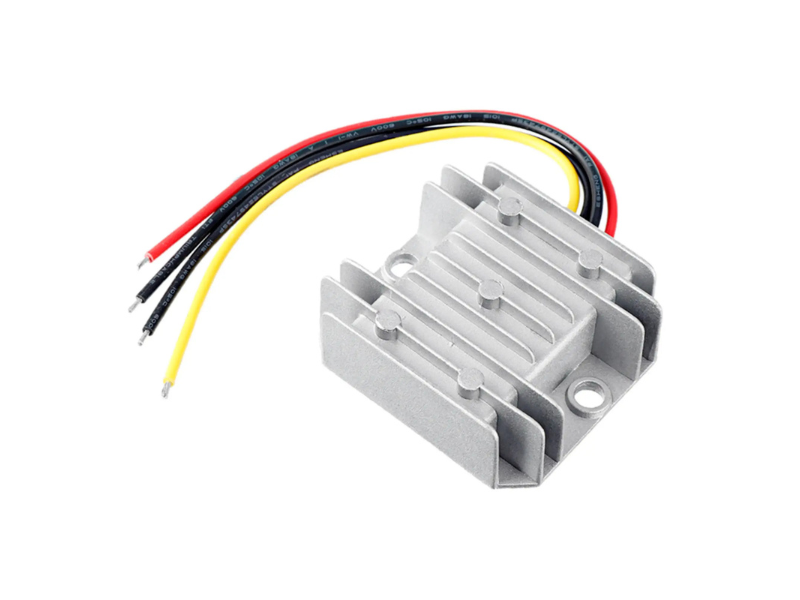

Advanced Materials and Packaging: The interface between a hot component and its heat sink is key. High-performance converters use Thermal Interface Materials (TIMs), such as conductive gap pads or greases, to fill microscopic air gaps between the semiconductor package and the heat sink. This ensures efficient heat transfer. The converter's own metal casing, often aluminum for its excellent thermal conductivity, acts as the primary heat spreader.

-

Active vs. Passive Cooling Strategies: The final step is moving heat from the converter's case into the environment. Passive cooling relies on natural convection and radiation from a finned heat sink. It is simple and highly reliable, with no moving parts. For higher power densities, active cooling is employed, typically using a fan to force air over the heat sink, dramatically increasing heat dissipation. The choice depends on the power level, available space, and ambient temperature.

Partnering for Thermal Success

Given these complexities, sourcing your DC DC Converter from a manufacturer with deep application knowledge is essential. A seasoned provider doesn't just sell a component; they offer a validated thermal solution.

They understand that a converter for a desert-based solar inverter faces different thermal challenges than one inside an automated guided vehicle (AGV) in a cold warehouse. Their design process involves extensive thermal simulation and real-world testing in environmental chambers, ensuring reliable performance across the specified temperature range. With a portfolio of hundreds of models developed over years of experience, such a manufacturer has likely already solved the thermal puzzle for applications in telecommunications, robotics, and medical equipment. They provide the assurance that the vital DC DC Converter in your system is both electrically sound and thermally robust for the long term.

Conclusion: The Keystone of Performance

In summary, thermal management in a DC DC converter is far more than a technical detail; it is the keystone that supports performance, reliability, miniaturization, and safety. It is the discipline that transforms a collection of electronic components into a dependable power solution. By prioritizing thermal design, engineers ensure the converters powering our technological progress do not falter under the heat they generate. When selecting a power solution, look beyond the electrical specs on the datasheet. Inquire about the thermal design. The longevity and success of your entire system may very well depend on it.

Recommended Products

Hot News

-

Application Advantages of Non-Isolated BUCK Converters Compared to Isolated Step-Down Converters

2024-01-23

-

DC-DC Converters Showcase Remarkable Advantages in Outdoor Off-Grid Applications

2024-01-23

-

DC to DC Battery Charger - Wide input and Noise immunity for dual battery system applications

2024-01-19

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

HY

HY

BN

BN

MN

MN