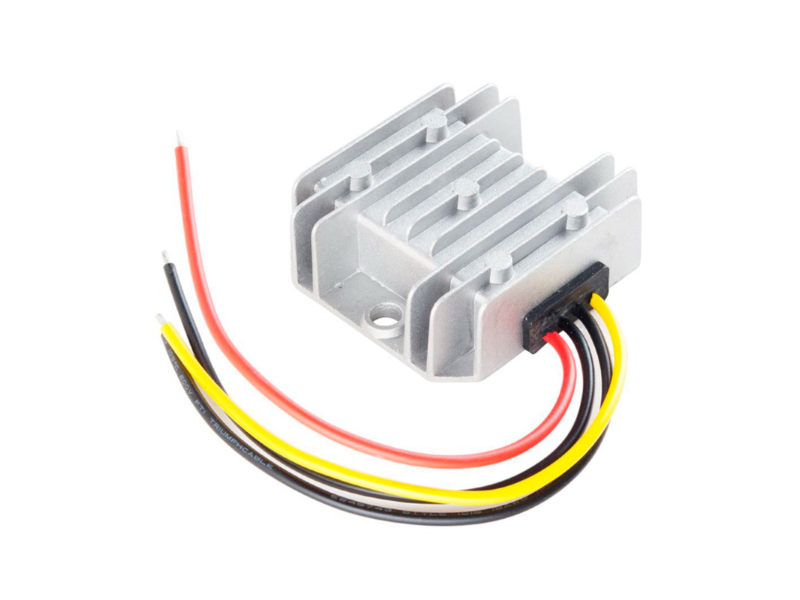

Common Problems of Buck Boost Converter and Solutions

If you're an electronic engineer working with circuits that require a specific voltage, you have likely come across a device called a Buck Boost Converter. These devices are extremely useful because they can adjust and modify voltages—stepping them up or down—and are commonly used in everything from portable gadgets to larger industrial equipment. However, they can sometimes be a hassle to work with and may require a good deal of patience to achieve reliable performance. This article draws upon frequently asked questions from the field, including insights from power supply specialists.

So, what are some of the most common headaches engineers face with these devices, and how can they be fixed? More details will be covered from a practical workbench perspective.

The Efficiency Puzzle: When the Converter Wastes Power

One of the first and most common issues with Buck Boost Converters is low efficiency. A design intended for energy-sensitive applications can underperform if too much input power is dissipated rather than delivered to the load. This wasted energy primarily converts into heat, which can lead to overheating and compromise the system's operation. High switching losses can occur if the MOSFETs in your circuit switch on and off too slowly or with excessive switching noise. Similarly, using an inductor with a high DC resistance (DCR) or poor core material can cause a significant portion of energy to be lost as heat within the component itself. Additionally, the diode in asynchronous designs—especially under high currents—can be another major source of loss. The solution isn't about finding one magic component; it lies in careful optimization. Consider using a controller with a more advanced switching algorithm, selecting MOSFETs with lower gate charge and on-resistance, and choosing higher-performance inductors.

To achieve optimal performance, many power electronics manufacturers adopt synchronous designs that replace the lossy diode with a secondary MOSFET. Transitioning to such a high-efficiency topology can lead to noticeable gains in performance and energy utilization.

Keeping Your Cool When Your Converter is Heating Up

Closely related to efficiency problems is the challenge of thermal management. A Buck Boost Converter that runs hot can degrade nearly every component—including the controller IC, MOSFETs, inductor, and capacitors—which jeopardizes the entire system's functionality. Excessive heat increases the risk of premature failure and undermines overall reliability. These thermal issues usually stem from electrical losses combined with inadequate cooling or poor thermal pathways. PCB layout plays a critical role here: cramming hot components like the inductor and MOSFETs into a corner without sufficient copper pour for heat dissipation can create localized thermal hotspots. Addressing these issues requires a two-fold approach: first, reduce heat generation by implementing the efficiency improvements mentioned earlier; second, improve heat dissipation through thoughtful PCB design. This includes using adequate copper planes connected to the thermal pads of power components, adding thermally conductive vias, and ensuring proper airflow within the enclosure.

In high-power designs, don't hesitate to incorporate a small heatsink. Professional DC-DC module makers understand that effective thermal management is integral to design—a cool converter is a reliable converter.

Stability and Noise: The Quest for Clean and Steady Power

One of the most frustrating issues to debug is instability and electrical noise. This can manifest as random output voltage oscillations, unexpected ringing, or high-frequency noise that interferes with other sensitive analog or RF circuits on the same board. These problems often originate in the control loop and physical layout. A poorly compensated feedback network can make the system unstable under certain load conditions, leading to voltage ringing or oscillation. Likewise, long or poorly routed high-current paths can introduce parasitic effects that generate electromagnetic interference (EMI). The ground plane design also plays a crucial role—if not carefully laid out, it can become a conduit for noise. Paying close attention to detail is key. Always follow the manufacturer's guidelines for stabilizing the feedback loop, using the recommended resistor and capacitor values. For layout, a best practice is to keep high-current loops as short as possible and group related components tightly to minimize parasitics and reduce EMI. Selecting the right bulk capacitance and high-frequency capacitors is equally essential to ensure the clean, stable power required by advanced applications.

System Design and Implementation Challenges

Beyond typical circuit design issues, successfully implementing a Buck Boost Converter often depends on practical considerations such as component selection and real-world operating conditions. Choosing components based solely on datasheet specifications can lead to unexpected problems. For instance, an inductor might have the correct inductance value yet saturate at the circuit's peak current, resulting in a sharp drop in efficiency and a spike in circuit noise. Similarly, electrolytic capacitors may overheat and experience impaired performance due to the thermal environment of the converter. Moreover, designs that work perfectly on the bench can fail in the field due to environmental factors like sudden temperature swings or vibration. The solution is to design with margin: derate components and anticipate real-world stresses. Select an inductor with a saturation current rating at least 20–30% above your calculated peak current. Use high-quality, low-ESR ceramic capacitors for decoupling, and consider robust polymer or tantalum capacitors for bulk filtering in high-temperature environments. Finally, always test prototypes across the full operating temperature range and under various load conditions.

This thorough validation process is what distinguishes a working prototype from a fully ruggedized, production-ready product capable of reliable performance across diverse applications. By focusing on robust design and thorough testing, engineers can ensure their power conversion systems deliver consistent and dependable performance.

Recommended Products

Hot News

-

Application Advantages of Non-Isolated BUCK Converters Compared to Isolated Step-Down Converters

2024-01-23

-

DC-DC Converters Showcase Remarkable Advantages in Outdoor Off-Grid Applications

2024-01-23

-

DC to DC Battery Charger - Wide input and Noise immunity for dual battery system applications

2024-01-19

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

HY

HY

BN

BN

MN

MN