Wengao Electronic: Writing the "Reputation Legend" in the Power Industry with Quality and Service

Commitment to Quality in Power Solutions

Precision Engineering for Reliable Performance

Precision engineering plays a critical role in delivering reliable power solutions, meeting both industry standards and performance benchmarks. Adhering to these standards ensures that products consistently deliver optimal efficiency and longevity. Advanced manufacturing techniques, like precision machining and 3D modeling, contribute significantly to the consistency and durability of power products. For instance, precise calibration in components such as a 12v DC power supply or car battery charger guarantees specific output levels, minimizing the risk of fluctuations that could compromise performance. This focus on precision not only improves efficiency ratings but also extends the operational lifespan of essential equipment, ultimately resulting in robust and reliable power solutions.

Stringent Testing Protocols for Power Stability

Stringent testing protocols are crucial for ensuring the stability and reliability of power products. Rigorous testing is implemented across the manufacturing process to identify and rectify any potential faults before products reach the market. This thorough testing is vital in preventing failures, as evident in data where untested devices exhibit higher failure rates compared to those subjected to extensive evaluations. Techniques such as simulation and stress testing are integral in the development process, providing insights into the product’s performance under various conditions. By employing these comprehensive methods, companies can ensure that their products, like power supply systems, deliver consistent power stability, reducing disruptions and increasing overall reliability.

Customer-Centric Service Excellence

Tailored Technical Support Solutions

Tailored technical support solutions are crucial for meeting specific customer needs and enhancing overall satisfaction. By customizing support services, companies can address unique operational challenges faced by their clients, leading to improved customer satisfaction and retention. For instance, a utility provider offering bespoke support can adapt its services to cater to different consumer demands, such as industrial power needs versus residential requirements. Case studies reveal that businesses providing customized support experience higher customer loyalty and more significant operational efficiency improvements. This is because when support is personalized, it aligns more closely with the customer's operational ecosystem, resulting in solutions that are not only more effective but also more reliable.

Proactive Maintenance & Warranty Programs

Proactive maintenance programs offer numerous benefits, including extending the lifespan and reliability of power products. These programs involve regular inspections and upkeep of equipment, ensuring potential issues are identified and addressed before they escalate into major problems. For instance, scheduling routine checks on transformers and power lines can prevent unexpected outages, ultimately reducing downtime and saving on emergency repair costs. Comprehensive warranty programs further enhance customer peace of mind by assuring continued support and minimizing total ownership costs. These warranty programs are especially advantageous, as they often result in decreased repair expenses and improved performance metrics—facts supported by data which show companies employing proactive maintenance experience fewer system failures and enhanced reliability, thereby safeguarding their services against unplanned interruptions.

Innovative Power Conversion Solutions

Isolated 48V-90V to 29.2V DC Charger for Lithium Batteries

The Isolated 48V-90V to 29.2V DC Charger is designed specifically for lithium battery applications, offering unique features that ensure longevity and safety. With its isolated design between the input and output, this charger is ideal for sensitive electronics in lithium batteries, including LiFePO4 and LiMn2O4 types. Its performance and efficiency are exemplified by a stable current output and an efficiency rating up to 90%, making it a standout solution in power conversion technology.

Potential applications extend to a range of sectors, such as automotive and renewable energy systems. For instance, electric vehicles can benefit from the charger's ability to manage various input voltages, making it resilient to changes in supply conditions. Similarly, renewable energy systems, like solar farms, find this charger useful for converting varying currents into a stable supply suitable for battery storage.

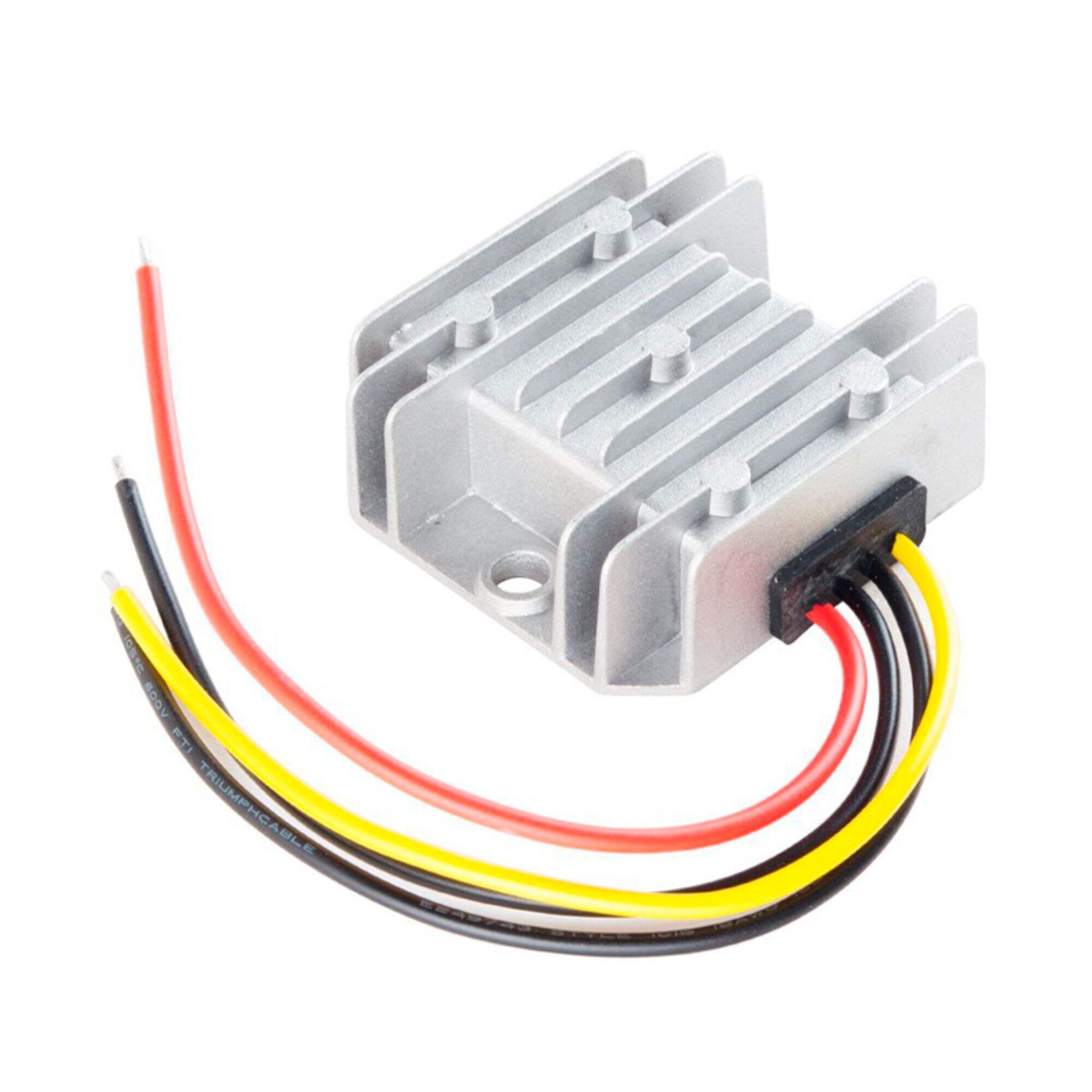

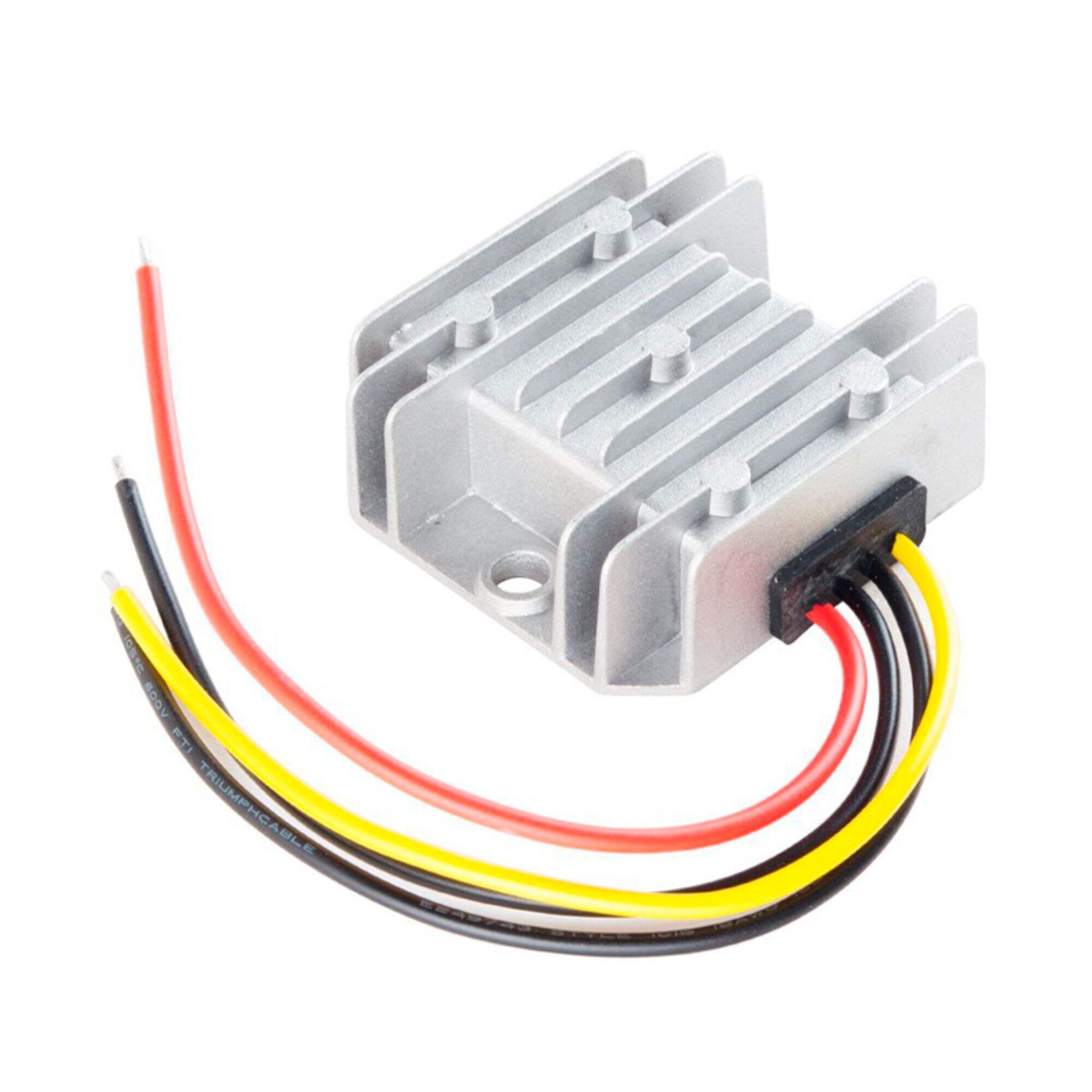

12V Voltage Stabilizer for Solar & Automotive Applications

The 12V voltage stabilizer plays a pivotal role in stabilizing power in both solar and automotive applications. It functions as a DC-DC buck-boost converter, converting a wide range of input voltages (8-40V) to a stable 12V output, ensuring consistent performance and reliability. This ensures that solar battery systems reliably manage energy produced during diverse sunlight conditions, improving energy efficiency and storage.

In automotive applications, this stabilizer enhances vehicle electronics' reliability by protecting against voltage fluctuations that could otherwise impact performance. With high efficiency up to 89.1%, it provides significant value by optimizing energy use, exemplifying its importance in modern solar setups and electric vehicles.

24V Buck-Boost Converter for Industrial Voltage Regulation

In industrial settings, the 24V buck-boost converter is crucial for voltage regulation, ensuring that machinery and equipment operate at optimal performance levels. This converter adjusts input voltages between 9-40V to a stable 24V output, preventing fluctuations that could affect operational stability. With an impressive efficiency rate of up to 96.9%, it stands out as a critical component in maintaining industrial efficiency.

Its competitive advantage lies in its non-isolated design, supporting a vast range of equipment and offering superior efficiency over traditional methods. This makes it a preferred choice in industries demanding high reliability and performance, from manufacturing floors to advanced robotic systems.

Advancing Power Industry Standards

Integrating Smart Technology in Energy Systems

Integrating smart technology within energy systems is vital for improving efficiency and reliability. Smart grids and devices enable precise monitoring and control, reducing energy wastage and enhancing operational efficiency. According to data from the International Smart Grid Action Network, smart technology adoption is linked to improved grid management and reduced outage durations—essential metrics for maintaining service reliability. Successful implementations, such as Italy's Enel's smart metering project, demonstrate substantial reductions in energy consumption and operational inefficiencies.

Sustainability-Driven Design Philosophy

Adopting a sustainability-driven design philosophy in the power sector prioritizes minimal environmental impacts and resource-efficient practices. This approach aligns companies with corporate social responsibility goals, catering to consumer demand for eco-friendly solutions. Industry studies, like those by the International Energy Agency, reveal strong market demand for sustainable power solutions—with projections showing an increase in investments of about 15% annually. This philosophy fosters innovation and positions companies competitively in the global market by prioritizing sustainable development in product design.

Recommended Products

Hot News

-

Application Advantages of Non-Isolated BUCK Converters Compared to Isolated Step-Down Converters

2024-01-23

-

DC-DC Converters Showcase Remarkable Advantages in Outdoor Off-Grid Applications

2024-01-23

-

DC to DC Battery Charger - Wide input and Noise immunity for dual battery system applications

2024-01-19

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

HY

HY

BN

BN

MN

MN